Glass, Metal, and Ceramic Substrates for Dye Sublimation Print Processing.

Question: Can dye sublimation printing be used on glass, metal, and/or ceramics?

Yes, but only with the right treatment. There are polymeric sprays that you can treat various materials with that create the right surface for dye sublimation printing.

Dye sublimation printing is perhaps one of the best and most effective printing methods available today, as well as being a cost-effective print method that produces high quality and long lasting and satisfying graphics on a wide variety of materials, from glass, ceramics, and metal to various polymer based fabrics.

Dye sublimation printing is perhaps one of the best and most effective printing methods available today, as well as being a cost-effective print method that produces high quality and long lasting and satisfying graphics on a wide variety of materials, from glass, ceramics, and metal to various polymer based fabrics.

Best Substrate for Dye Sublimation

Of course, it is best to print dye sublimation to white or at least close to white substrates. Whether you’re printing mesh baseball caps, polyester patches, ceramic plates, mouse pads, license plates, MDF hardboard (like a clipboard), ceramic tiles, jackets/shirts, beverage insulators, poly calendars, doll patches, banners, flags, displays, polyester fabric posters, metal clock faces, key chains, plastic coasters, photo plates, etc.

All of these are available in white or off-white materials and with that being the case, it is simple to print with beautiful continuous tone dye sub printing.

Different Dye Sublimation Printer Sizes

There are a couple different main sizes of printers for dye sublimation printing. The larger, wider format printers are mostly used for fabric printing, which includes clothing fabrics as well as display fabrics.

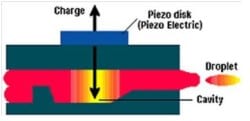

Small format dye sublimation printing requires a desktop printer that is capable of using dye sublimation inks, but also contains “piezo electric print heads” – and not a printer that utilizes heat in the printing process. Epson owns the patent on these print heads, although they do lease it to other printer companies, I am told.

These print heads utilize an electric charge that causes the dye molecules to flex when the electrical current flows through it. As the charge hits the ink droplet, it forces it to spray out of the ink nozzle creating the print, but without heat. The reason this is important is because dye sub inks are heat reactive. You don’t want them turning to gas during the printing, but rather only in the transfer process as would happen with standard inkjet print heads.

These print heads utilize an electric charge that causes the dye molecules to flex when the electrical current flows through it. As the charge hits the ink droplet, it forces it to spray out of the ink nozzle creating the print, but without heat. The reason this is important is because dye sub inks are heat reactive. You don’t want them turning to gas during the printing, but rather only in the transfer process as would happen with standard inkjet print heads.

Super High Resolution is not Necessary

One thing to note in passing…it is never necessary to print super high resolution with a dye sub printer. 1440 dpi is more than enough, and most of the time 720dpi is just fine. When the dye turns to gas in the sublimation process, creating the continuous tone that dye sub prints are famous for, most of the refinement that is offered by the higher resolution printing is lost because the dyes flow together during the heated dye sublimation process.

So, what do we print to when we’re creating any of the above products? First we print to a high quality transfer paper that is treated specially for the dye sublimation printing process. We don’t use a low quality paper because it affects the print quality.

Click here to see graphics that can be done through dye sublimation printing process.

Popular Posts: