In this article, you will know how to get those gorgeous color prints through dye Sub banner printing, plus, how grommets differ from pole pockets.

Questions: How do you get such gorgeous colors on your fabric banners?

Our polyester fabric banners are printed using the heat transfer or dye sublimation printing method. This method uses heat and pressure to create nearly photographic reproduction of your images on fabrics from knits to satins to sheer fabrics.

The Process of Dye Sublimation Printing

The way the dye sublimation printing process works with fabric is this. First, the dye, which is slightly different than ink in that it is CMYO (cyan-magenta-yellow-overprint) rather than CMYK (cyan-magenta-yellow-black) which is the traditional color palette for digital and screen printing, is printed directly to a transfer paper.

The way the dye sublimation printing process works with fabric is this. First, the dye, which is slightly different than ink in that it is CMYO (cyan-magenta-yellow-overprint) rather than CMYK (cyan-magenta-yellow-black) which is the traditional color palette for digital and screen printing, is printed directly to a transfer paper.

Once the paper is printed, it is married to a piece of polyester fabric. Why polyester? Polyester is a synthetic oil-based fabric, so its cellular structure is closed, unlike cotton or silk, which cannot be dye sublimation printed, at least not at this writing. When heated, the cells open. This is important when the fabric and paper are sent through the heated rollers at around 400ºF.

As the paper and fabric go through the heated rollers, the cells of the poly fabric open to accept the dye, which is converted to a gaseous state due to the heated rollers. This is where the term dye sublimation comes from. The dye is sublimated into the cellular structure of the polyester and actually becomes part of the fabric, which is why the colors are so durable and also why we get those gorgeous colors, like a photograph. This color is called continuous tone printing, because it doesn’t rely on dots of color like digital printing does.

There’s more about dye sublimation printing on polyester fabrics. Read in here: https://www.visigraph.com/fabric-vinyl-cloth-banners/dye-sublimation-satin-fabric-cloth-banners/

Question: What is the difference between grommets and pole pockets?

There are several ways to hang banners, and those are two of the most common ways, with velcro being a 3rd way, although you have to have hook velcro on a wall or object to attach the loop velcro to.

Grommets

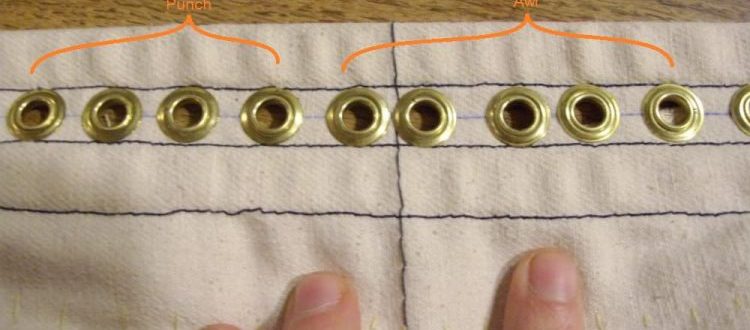

Essentially, grommets are either metal or plastic rings that come in two parts, called the grommet and the washer. First, your material needs to be less thick by at least 1/16” than the depth of the grommet. A hole is punched in the material, say a vinyl banner, and the grommet is inserted thru the bottom, then set into the bottom setting die.

Essentially, grommets are either metal or plastic rings that come in two parts, called the grommet and the washer. First, your material needs to be less thick by at least 1/16” than the depth of the grommet. A hole is punched in the material, say a vinyl banner, and the grommet is inserted thru the bottom, then set into the bottom setting die.

The washer is placed over the throat of the grommet, then, if this is the simplest method, a hammer is used on the top setting punch tool and the grommet is set. Other methods are the manual grommet setter and the pneumatic grommeting machines which can be fed manually, or in larger plants may be fed with materials automatically.

Pole Pockets

A pole pocket is simpler to describe, and is favored by some for hanging banners, particularly indoors. Grommets are more common out of doors where banners are hung between light poles or trees or pinned to the side of buildings with concrete anchor pins or the like. Indoors, banners tend to be smaller which favors pole pockets to a degree.

When a banner is printed, it is hemmed with a fabric loop on the top and sometimes the bottom, and less frequently the sides (unless it is a retail display or a trade show display or backdrop). A pole can be inserted through this pocket, and some type of hanging apparatus connected to each end and hung from the ceiling.

Other Alternative to Consider

Although you didn’t ask, I will also talk about velcro. Velcro comes with a loop component and a hook component. It comes either with adhesive backing or not, depending if it’s being sewn to something like a banner. The adhesive side will be attached to frames or the like, and a banner with velcro sewn to it will be attached quickly and simply.

Popular Posts: