Using dye sublimation printers – the special paper and the process of large format dye sub printing.

Question: What are Dye sublimation printers used for?

Dye sublimation printers are used mainly for making prints on polyester fabric. The fabric can be used for clothing or advertising media, such as teardrop banners, “L” banners, hanging banners, flag banners, tradeshow displays, backdrops, X Banners, roll up or pop up banners, retractable banners, etc., etc.

Dye and Ink Color Spectrum

Dye sublimation printing is different from other types of printing in that it uses dyes rather than ink, like inkjet or laser jet printers do. Inkjet printers use the CMYK color spectrum (Cyan, Magenta, Yellow, Black), which is the print industry standard for most printing worldwide (RGB color spectrum is used for most video, in contrast).

Dye sublimation printing is different from other types of printing in that it uses dyes rather than ink, like inkjet or laser jet printers do. Inkjet printers use the CMYK color spectrum (Cyan, Magenta, Yellow, Black), which is the print industry standard for most printing worldwide (RGB color spectrum is used for most video, in contrast).

Dye sublimation uses the CMYO spectrum, where the “O” represents a clear overprint which becomes the black when exposed to heat and pressure.

The Printing Process

When printing using dye sublimation printing, also known as heat transfer dye sublimation printing, or dye sublimation heat transfer printing, first, the image is printed to a transfer paper using the CMYO ink set, then, once the paper is removed from the printer, it is matched up to a polyester fabric and place on a pressure rolling machine with heated rollers (around 400ºF/204ºC) and slowly rolled between the rollers until it comes out the back side with a perfect (hopefully) image sublimated to the fabric.

What Sublimation Means

The term “sublimation” has to do with the chemistry of the dye, which, when reacting to the heat and pressure of the heated rollers, becomes a gas and infuses itself permanently into the fabric. Thus, the term most commonly used for this type of printing, sublimation printing or dye sublimation printing.

Question: What kind of paper do you use for dye sublimation printing?

The type of paper used for dye sublimation printing is typically called “dye sublimation transfer paper,” or just “dye sublimation paper.” I know – it should have a fancier pedigree for the king of printing processes, but that’s it. I explained above how dye sublimation paper works, so if you want to know how it works, read the Q & A above.

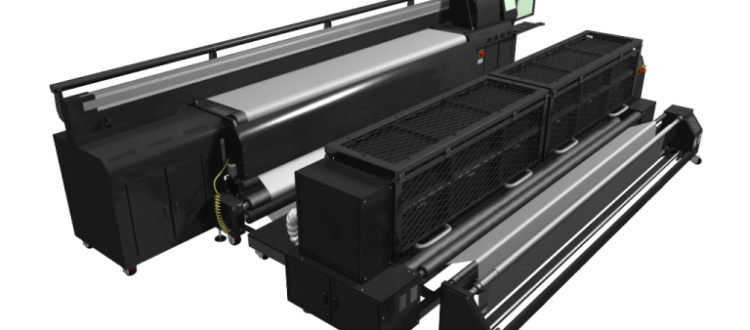

Question: Do you have any information on large format dye sublimation printing? How is this done?

Dye sublimation printing is done on variably sized printers. So, if you want a large format sublimation print, you simply need to find a dye sub printer that has a 3.2 meter printer (just over 10 ft.), and they will be happy to print whatever you need printed and as large as you want it.

Dye sublimation printing is done on variably sized printers. So, if you want a large format sublimation print, you simply need to find a dye sub printer that has a 3.2 meter printer (just over 10 ft.), and they will be happy to print whatever you need printed and as large as you want it.

Now, if there is a dimension larger than 3.2 meters (a meter is around 39 inches), what will have to happen is that the printer will choose a spot where there is no copy or complex graphics and fuse two pieces together at that spot. This is very commonly done where over-sized banner backdrops are used on stages or at trade shows, for instance.

Because of the difficulty of marrying the sublimation transfer paper to the material the larger it gets, many companies are now electing to use direct to fabric substrate printing. It is really more of an inkjet printing process, but the inks are formulated to fuse to the poly fabrics similar to dye sublimation printing, so the net result is very similar.

Popular Posts: