If you did a Google or Yahoo! query for the term sublimation fabric printing, in all likelihood you are looking for a company that does it for banners, trade show graphics, cloth posters, or flags.

You also may have been looking for textile print company that does it, although more than likely, with its increasing popularity as an advertising medium, you are looking for the former.

Why Sublimation Printed Cloth Fabric Banners Will Always Impress Your Clientele

I have penned several articles regarding this method of printing, also known as dye sublimation, in which I’ve noted that it is a relative newcomer to the graphic and advertising industry. In the past several decades, the most common form of portable large format advertising has been the vinyl banner. It is still outstanding for exterior usage, and is used on the sides of buildings all over the world, on billboards, and even on truck trailers that are fitted with banner frames.

In upscale business environments, though, a new trend is rapidly developing, one that started a decade or so ago. Many companies are now opting for sublimated graphics on various polyester or nylon fabrics as it solves the plastic-like appearance of vinyl displays, which, quite frankly, can appear somewhat cheap to the viewer. Tradeshow displays, upscale retail stores, convention centers – many of these now utilize cloth prints to express their differences from the neighboring booth or store. It is also made one-off full color photographic printing affordable to smaller and mid-size companies without going to the bank or selling of a division of the company.

Ink + Fabric + Heat + Pressure = Happy Clients

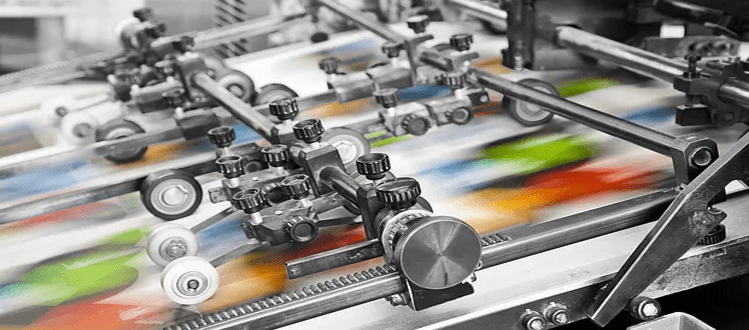

So, what is sublimation fabric printing? The press of display components or banners is done with the use of a wide format digital printer that can handle either 60″ materials or 120″ material (or both in the case of the latter). These printers are specifically made to embed dye inks which are different from a standard wide format inkjet printer in that they use a CMYO ink set versus the CMYK The O may be either gray or clear, but either way, it ends up black. This dye is printed onto a transfer paper which will then be married to a fabric.

So, what is sublimation fabric printing? The press of display components or banners is done with the use of a wide format digital printer that can handle either 60″ materials or 120″ material (or both in the case of the latter). These printers are specifically made to embed dye inks which are different from a standard wide format inkjet printer in that they use a CMYO ink set versus the CMYK The O may be either gray or clear, but either way, it ends up black. This dye is printed onto a transfer paper which will then be married to a fabric.

The type of cloth that needs to be used in will be high in polymers. These fabrics will include polyester and nylon, although polyester is most popular for interior usage, whereas nylon is more common outdoors and is used with feather banners and the like. Cotton, which is usually printed using a screen-printing press (as in T-shirts), has no polymers and therefore can’t be used in this press method.

Furthermore, the process takes place when the transfer sheet, which is attached to the polyester fabric, is run through hot rollers. The heat and pressure combine to convert the dye into a gaseous state – but not a liquid state – which then combines with the polymers in the fabric to create a beautiful continuous-tone fabric print. Many of our clients have full color ad prints that they want us to transfer to polyester fabric because the results are outstanding.

As I intimated above, the process brings out a continuous tone pattern, whereas an inkjet-to-vinyl printer uses a dot pattern which lays down the CMYK color spectrum – one color at a time (although in close succession) – to achieve a similar look, although not nearly as photographic. This is why many of our clients are moving away from vinyl banners to fabric. It just has a rich, photo-quality look to it.

When you consider your next banner, trade show display or other advertising piece, you may want to consider how that print enhances your business’s image, then consider using sublimation fabric printing. Visit here to grab more ideas when it comes to this type of print method.

Good Read! Can I get a quote NOW!?

Popular Posts: