This is what you need to learn about direct-to-garment or DTG printing.

Question: What is DTG Printing?

DTG is an acronym for Direct to Garment printing. Other terms for this include, but are not limited to, digital direct to garment printing, inkjet to garment printing, and digital apparel printing.

The Process of Direct to Garment Printing

The DTG printing process involves printing directly to textiles or clothing with a modified inkjet printer that is specifically designed to print garments. It requires a specialized platen and inks that are formulated specifically for cloth textile printing. These inks are printed directly to the fabric, unlike dye sublimation textile printing or heat transfer printing which uses a paper carrier which transfers the dye image using a combination of heat and pressure.

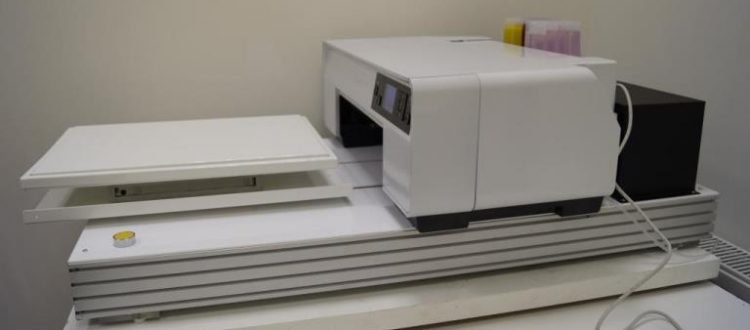

Direct to Garment Printer

The basic technology used to build a DTG inkjet printer is the same technology used to build an inkjet printer similar to those used in homes and offices worldwide, except they cost a lot more, sometimes a lot more, depending on the type of output the printer will produce. Faster, bigger, and better machines can cost upwards of $300K.

The basic technology used to build a DTG inkjet printer is the same technology used to build an inkjet printer similar to those used in homes and offices worldwide, except they cost a lot more, sometimes a lot more, depending on the type of output the printer will produce. Faster, bigger, and better machines can cost upwards of $300K.

DTG Printing “officially” became a commercial enterprise in approx. 2004 when the first DTG inkjet printers were introduced at a large trade show for printers put on by the Specialty Graphic Imaging Association (SGIA) in Minneapolis, Minnesota (USA). Since the original units were introduced in 2004, many other printer manufacturing companies have jumped into the fray, and the speed and resolution have increased significantly over the past 10 years.

Why We Have the Option for DTG Printing on Fabrics

1. Cotton and other Natural-fiber Fabrics cannot be dye sublimated.

One of the reasons for DTG printing, though, is that cotton and other natural-fiber cloth fabrics cannot be dye sublimation printed, due to the porosity of the fibers. Poly fabrics like polyester and nylon can by “printed” with dyes during the heat transfer from the transfer paper to the fabric because they are closed fibers that open up and encase the dye then close again as they cool. Natural fibers are not able to accomplish this, so inks were invented that would fill the gap, so to speak, using inkjet printing technology.

Natural fabrics have been printed for decades using inks that were compatible with cotton, but with the advent of dye sublimation printing, it became the challenge to create the inkjet printers that could print cotton and other natural fibers with similar results, although, in my opinion, the colors don’t pop as well on the natural fibers, possibly because they are natural fibers.

2. Drive RIP Software to multiple inkjet printers.

As with most inkjet printing, most printers are driven by computers that have RIP software. RIP stands for raster image processor. These processing programs dictate the quantity of ink used as well as sending information on the shirt color (dark clothing requires a white base coat under the image to be printed). Some RIP software (more costly versions usually) are able to “drive” multiple inkjet printers.

3. Print T-shirts in small quantities without setting up multiple screens for printing.

The main reason direct-to-garment printing was developed was to create a way to print small quantities of shirts without the cost of having to set up multiple screens to print just a few shirts or a few dozen shirts. You could actually print a single shirt with this technology. That would likely be an expensive T-shirt, but some people have the budgets to afford a single shirt made to order, so the DTG printers were invented.

The main reason direct-to-garment printing was developed was to create a way to print small quantities of shirts without the cost of having to set up multiple screens to print just a few shirts or a few dozen shirts. You could actually print a single shirt with this technology. That would likely be an expensive T-shirt, but some people have the budgets to afford a single shirt made to order, so the DTG printers were invented.

However, compared to printing one t-shirt using traditional screen printing methods, DTG printing is very cost effective. However, with everything that is computerized, the equipment and inks are costly, although the results are typically cleaner and more concise compared with screen printing.

Popular Posts: