Full color label printing is a modern printing technique that allows for the creation of high-quality, full-color labels with a variety of design options. This printing method uses advanced technology to produce vivid, detailed images and text that can be printed on a wide range of label materials.

With full color label printing, businesses can create eye-catching labels that grab the attention of potential customers and help their products stand out on store shelves. This printing technique is ideal for businesses that need to print small to large-sized label runs, and it offers a cost-effective solution for creating professional-looking labels without the need for expensive equipment or technical expertise.

What is 4CP Full Color Label Printing?

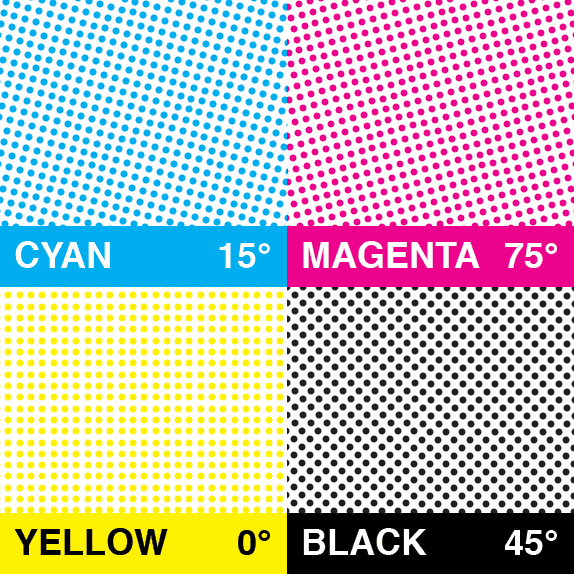

4CP full color label printing is a printing technique that uses four colors (cyan, magenta, yellow, and black) to create a wide range of colors and shades. This printing method is also known as CMYK printing, and it is commonly used in the printing industry for producing high-quality, full-color labels. With 4CP full color label printing, businesses can create labels with vibrant, eye-catching colors and intricate designs that are sure to stand out on store shelves.

In 4CP Label Printing, Why K for Black?

In 4CP label printing, the “K” stands for black because it is the key color in the printing process. The other three colors used in 4CP printing (cyan, magenta, and yellow) are subtractive colors, meaning they are mixed together to create a range of colors. However, when all three colors are mixed together in equal parts, they create a muddy brown color instead of black.

In 4CP label printing, the “K” stands for black because it is the key color in the printing process. The other three colors used in 4CP printing (cyan, magenta, and yellow) are subtractive colors, meaning they are mixed together to create a range of colors. However, when all three colors are mixed together in equal parts, they create a muddy brown color instead of black.

To avoid this issue, black ink is added to the printing process as a separate color. This allows for a wider range of shades and hues to be created, as well as providing a true black color for text and other elements of the label. Using black ink also helps to save on the amount of ink used overall, which can help to reduce printing costs and improve the quality of the final product.

Spot Colors Versus 4 Color Process Labels

Spot colors and 4 color process labels are two different printing techniques used in label printing. Spot colors involve using premixed ink colors to create a specific color that matches a particular brand or design. This technique is often used for logos or other elements that require a specific color to be consistent across all labels.

On the other hand, 4 color process labels use a combination of four colors (cyan, magenta, yellow, and black) to create a wide range of colors and shades. This printing technique is ideal for printing complex designs, photographs, and other images with a wide range of colors. While spot colors offer consistency, 4 color process labels provide a wider range of color options and can be more cost-effective for larger label runs. The two methods can also be combined when required.

How to Achieve Crisp Images and Color Accuracy?

Achieving crisp images and color accuracy with full color label printing requires attention to detail and the use of high-quality printing equipment. To start, it is important to use high-resolution images and graphics that are optimized for printing. This will help to ensure that the final product has crisp, clear lines and vibrant colors.

Achieving crisp images and color accuracy with full color label printing requires attention to detail and the use of high-quality printing equipment. To start, it is important to use high-resolution images and graphics that are optimized for printing. This will help to ensure that the final product has crisp, clear lines and vibrant colors.

Also, it is important to work with a printing company that uses the latest equipment and print file management to produce high-quality labels. This may include using digital printing technology, which can produce sharper images and more accurate colors than traditional printing methods. Finally, it is important to work with a printing company that offers color matching services to ensure that the colors on the label match the original design as closely as possible.

Can You Print Labels in Full Color?

Yes, labels can be printed in full color using a variety of printing techniques. Full color label printing, also known as 4 color process printing, uses four colors (cyan, magenta, yellow, and black) to create a wide range of colors and shades. This printing technique is ideal for printing labels with complex designs, photographs, and other images with a wide range of colors.

In addition, spot color printing can be used to create labels with specific colors that match a particular brand or design. This technique involves using premixed ink colors to create a specific color that is consistent across all labels. Ultimately, the choice of printing technique will depend on the specific needs of the business and the design requirements of the label.

What is the Best Printer for Coloured Labels?

The best printer for colored labels will depend on the specific needs of the business and the volume of labels that need to be printed. For small to medium-sized label runs, digital printers are a popular choice for full color label printing. Digital printers offer high-quality printing, fast turnaround times, and the ability to print on a wide range of label materials. They can also produce variable data labels, which are labels that have unique information printed on each label, such as barcodes or sequential numbers.

The best printer for colored labels will depend on the specific needs of the business and the volume of labels that need to be printed. For small to medium-sized label runs, digital printers are a popular choice for full color label printing. Digital printers offer high-quality printing, fast turnaround times, and the ability to print on a wide range of label materials. They can also produce variable data labels, which are labels that have unique information printed on each label, such as barcodes or sequential numbers.

For larger label runs, flexographic printing may be a better option. This printing technique is ideal for printing high volumes of labels at a lower cost per label. Flexographic printing can also produce high-quality, full color labels with a range of finishes and textures.

Do You Need a Special Printer to Print Labels?

Yes, you may need a special printer to print labels, depending on the specific needs of the business. While some businesses may be able to use a standard inkjet or laser printer for printing labels, others may require specialized equipment for printing high-quality, professional-looking labels.

For example, businesses that need to print large volumes of labels may require a dedicated label printer that can handle high-speed printing and large label rolls. Also, businesses that need to print labels with specific colors or finishes may require a printer that can accommodate specialized ink or label materials.

Can a Normal Printer Print Labels?

Yes, a normal printer can print labels, but the quality and durability of the labels may not be suitable for professional/commercial applications. For basic label printing needs, a standard inkjet or laser printer can be used to print labels on standard label sheets. However, the print quality of the labels is rarely as high as those printed on specialized label printers, and the labels may not be as durable or resistant to water and other environmental factors.

Additionally, using a standard printer for label printing may not be cost-effective for larger label runs, as the cost per label may be higher than with specialized label printing equipment. It is important to work with a printing company that can provide guidance on the best printing equipment for your specific label printing needs.

What Substrate is Used for Full Color Label Printing?

Full color label printing can be done on a variety of substrates, depending on the specific needs of the label. Some common finishes used for full color label printing include glossy, matte, and uncoated, which all can be done on PVC, paper, static cling, polyester, foils, BOPP, polypropylene, etc etc. Gloss finishes are a popular choice for labels that require a high-shine finish, while matte finishes are ideal for labels that require a softer, muted finish. Uncoated substrates may be the right choice for labels that require a natural, organic look and feel.

Full color label printing can be done on a variety of substrates, depending on the specific needs of the label. Some common finishes used for full color label printing include glossy, matte, and uncoated, which all can be done on PVC, paper, static cling, polyester, foils, BOPP, polypropylene, etc etc. Gloss finishes are a popular choice for labels that require a high-shine finish, while matte finishes are ideal for labels that require a softer, muted finish. Uncoated substrates may be the right choice for labels that require a natural, organic look and feel.

Ultimately, the choice of substrates will depend on the specific needs of the label, such as the desired finish, durability, and resistance to environmental factors.

What Paper Size Should You Use to Print Full Color Labels?

The paper size used to print full color labels will depend on the size and shape of the label needed for the specific application. It is important to work with a printing company that can provide guidance on the best sizing and die cuts for your specific label printing needs, based on the size and shape of the label and the volume of labels that need to be printed.

Is It Cheaper to Print Your Own Full Color Labels or Buy Them?

Whether it is cheaper to print your own full color labels or buy them depends on several factors, such as the volume of labels needed, the cost of printing equipment, and the cost of materials. For small label runs, it may be more cost-effective to print labels in-house using a standard inkjet or laser printer and pre-cut label sheets.

However, for larger label runs, it may be more cost-effective to outsource label printing to a professional printing company that has specialized equipment and can offer bulk pricing. Also, outsourcing label printing can ensure that the labels are of high quality and meet the specific needs of the business, such as durability and resistance to environmental factors.

Conclusion

Full color label printing can be an effective way to showcase a brand and add value to a product. When considering 4CP label printing, it is important to determine the specific needs of the business, such as label size, shape, and durability, as well as the volume of labels needed. Depending on these factors, businesses may choose to print labels in-house using standard inkjet or laser printers, or outsource label printing to a professional printing company that has specialized equipment and can offer bulk pricing. Ultimately, 4-color label printing can be a cost-effective way to add value to a product and enhance the overall branding of a business.

Popular Posts: