High resolution digital full color sticker printing is a modern and innovative printing process that allows for the creation of high-quality stickers with vibrant colors and intricate designs.

This printing technique utilizes digital printing technology to produce stickers that are durable, long-lasting, and visually appealing. With the ability to print on a variety of materials, including vinyl, paper, and polyester, high resolution digital full color sticker printing has become a popular choice for businesses, organizations, and individuals looking to create custom stickers for branding, marketing, or personal use. Whether you need stickers for your business, event, or personal project, high resolution digital full color sticker printing offers a cost-effective and efficient way to produce high-quality stickers that will make a lasting impression.

How Does Full Color Sticker Printing Works

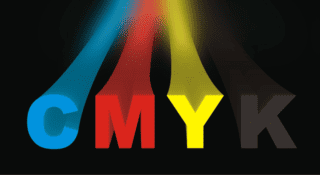

Full color sticker printing is a digital printing process that uses advanced technology to produce high-quality stickers with vibrant colors and intricate designs. The process begins with the creation of a digital file that contains the artwork or design to be printed on the sticker. This file is then uploaded to a specialized printer that uses four primary colors – cyan, magenta, yellow, and black (CMYK) – to create a full spectrum of colors.

The printer applies tiny droplets of ink to the sticker material in a precise pattern, layer by layer, until the final image is formed. The result is a high-resolution, full-color sticker that is both durable and visually appealing. Depending on the type of material used, the stickers can be cut to any shape or size, making them a versatile and customizable option for a wide range of applications.

What Color Mode is Best for Printing Full Color Stickers

When it comes to printing full color stickers, the best color mode to use is CMYK. CMYK stands for Cyan, Magenta, Yellow, and Key (black), and is the standard color model used in printing. This color mode is specifically designed for printing purposes, and it ensures that the colors in the final printed product match the colors in the original design as closely as possible. CMYK color mode uses a subtractive color process, meaning that it starts with white and subtracts color by adding ink.

When it comes to printing full color stickers, the best color mode to use is CMYK. CMYK stands for Cyan, Magenta, Yellow, and Key (black), and is the standard color model used in printing. This color mode is specifically designed for printing purposes, and it ensures that the colors in the final printed product match the colors in the original design as closely as possible. CMYK color mode uses a subtractive color process, meaning that it starts with white and subtracts color by adding ink.

This is different from the RGB color mode, which is used for digital displays and starts with black and adds color by emitting light. Using the CMYK color mode ensures that the colors in your full color sticker design are accurately represented in the final printed product, resulting in a high-quality and visually appealing sticker.

Is It Better to Use CMYK or RGB for Full Color Sticker Printing?

When it comes to full color sticker printing, it is better to use the CMYK color mode rather than RGB. CMYK is a color model specifically designed for printing purposes, while RGB is used for digital displays. The CMYK color mode uses a subtractive color process, meaning that it starts with white and subtracts color by adding ink. This is different from the RGB color mode, which is used for digital displays and starts with black and adds color by emitting light.

Using the RGB color mode for printing can result in colors that are not accurately represented in the final printed product, as the RGB color space is much larger than the CMYK color space. This can lead to colors that are too bright or saturated, or that cannot be accurately reproduced using CMYK inks. Therefore, it is always recommended to use the CMYK color mode when creating designs for full color sticker printing to ensure that the colors in the final product match the original design as closely as possible.

Should I Convert Images to CMYK Before Printing Full Color Stickers?

Yes, it is recommended to convert images to CMYK before printing full color stickers. This is because the CMYK color mode is specifically designed for printing purposes, and it ensures that the colors in the final printed product match the colors in the original design as closely as possible.

Yes, it is recommended to convert images to CMYK before printing full color stickers. This is because the CMYK color mode is specifically designed for printing purposes, and it ensures that the colors in the final printed product match the colors in the original design as closely as possible.

If images are not converted to CMYK before printing, the colors in the final printed product may not be accurately represented, resulting in a sticker that looks different from the original design. Also, converting images to CMYK allows you to see how the colors will look in the final printed product, which can help you make any necessary adjustments to the design before printing.

Do You Need to Add Bleed When Printing Full Color Stickers?

Yes, it is important to add bleed when printing full color stickers. Bleed is the area outside of the design that extends beyond the final size of the sticker. Adding bleed ensures that the design extends all the way to the edge of the sticker, and it also allows for any slight variations in the printing or cutting process. Without bleed, there may be white space or gaps between the design and the edge of the sticker, which can make the final product look unprofessional. The amount of bleed required may vary depending on the printing and cutting process, but it is typically recommended to add at least 1/8 inch of bleed to the design.

What are High Quality Full Color Stickers Made Of?

High quality full color stickers can be made of a variety of materials, depending on the intended use and application.

Vinyl: One popular material for full color stickers is vinyl, which is a durable and weather-resistant material that can be used both indoors and outdoors. Vinyl stickers are available in a range of finishes, including glossy, matte, and clear, and can be cut to any shape or size.

Polyester: Another material used for high quality full color stickers is polyester, which is a synthetic material that is known for its durability and resistance to tearing and wrinkling. Polyester stickers are often used for outdoor applications, such as bumper stickers, as they are resistant to water, UV rays, and other environmental factors.

Both vinyl and polyester stickers can be printed using high resolution digital full color printing, which produces vibrant colors and sharp, detailed images.

Standard and Custom Shapes for Full Color Sticker Printing

Full color sticker printing offers a wide range of standard and custom shapes to choose from. Standard shapes include circles, squares, rectangles, and ovals, as well as more unique shapes like stars, hearts, and triangles. These shapes are pre-designed and readily available for printing, making them a cost-effective option for many applications. However, custom shapes are also available for those looking to create a more unique and personalized sticker.

Full color sticker printing offers a wide range of standard and custom shapes to choose from. Standard shapes include circles, squares, rectangles, and ovals, as well as more unique shapes like stars, hearts, and triangles. These shapes are pre-designed and readily available for printing, making them a cost-effective option for many applications. However, custom shapes are also available for those looking to create a more unique and personalized sticker.

Custom shapes can be created using a die-cutting process, which involves cutting the sticker material into a specific shape using a sharp metal die. This process allows for a high degree of customization and creativity, as almost any shape can be created. Custom shapes are ideal for branding and marketing purposes, as they can be designed to match a company logo or product.

Full Color Sticker Printing Finish Options

Full color sticker printing offers a variety of finish options to choose from depending on the desired look and application:

- Glossy: One popular finish option is glossy, which provides a shiny and reflective surface that enhances the vibrancy of the colors and adds a professional look.

- Matt Finish: Matte finish provides a non-reflective surface that can give stickers a more subtle and sophisticated appearance.

- Clear Finish: Clear finish is also an option, which allows the design to be printed on a clear material, giving the appearance of a transparent sticker. This option is ideal for designs that incorporate negative space or are meant to blend in with the surface they are applied to.

- Metallic Finish: There is also a metallic finish option, which adds a metallic sheen to the design, giving it a unique and eye-catching appearance.

How Do You Seal Full Color Stickers After Printing?

Sealing full color stickers after printing can help protect them from wear and tear, as well as from exposure to the elements. One common method for sealing stickers is to use a clear coat spray, which can be applied to the surface of the sticker after it has been printed and allowed to dry. Clear coat spray is available in both gloss and matte finishes, and can be used to add an extra layer of protection to the sticker without affecting the appearance of the design.

Another method for sealing stickers is to use a clear vinyl laminate, which is a thin, transparent film that is applied over the surface of the sticker. Vinyl laminate provides a more durable and long-lasting protection for the sticker, and is ideal for outdoor applications or stickers that will be subject to heavy use.

Are Full Color Stickers Weather Resistant?

Yes, full color stickers can be weather resistant, depending on the material and finish used in the printing process. Vinyl and polyester are two materials commonly used for full color stickers that are known for their durability and resistance to the elements. Vinyl stickers, in particular, are often used for outdoor applications, as they are resistant to water, UV rays, and other environmental factors that can cause damage or fading.

Yes, full color stickers can be weather resistant, depending on the material and finish used in the printing process. Vinyl and polyester are two materials commonly used for full color stickers that are known for their durability and resistance to the elements. Vinyl stickers, in particular, are often used for outdoor applications, as they are resistant to water, UV rays, and other environmental factors that can cause damage or fading.

Additionally, the finish used on the sticker can also affect its weather resistance. Glossy finish is often preferred for outdoor stickers, as it provides a protective layer that can help prevent damage from exposure to the elements. Matte finish, on the other hand, may be more susceptible to damage from moisture and sunlight. Overall, full color stickers can be weather resistant, but it is important to choose the right materials and finish for the intended application to ensure maximum durability and longevity.

How Long Do Full Color Stickers Last?

The lifespan of full color stickers can vary depending on a number of factors, including the material used, the finish, and the environment in which they are used. Vinyl and polyester are two materials commonly used for full color stickers that are known for their durability and longevity. When properly cared for and used in appropriate environments, these stickers can last for several years. The finish used on the sticker can also affect its lifespan, with glossy finishes typically lasting longer than matte finishes.

Also, exposure to sunlight, moisture, and other environmental factors can cause stickers to fade or deteriorate more quickly. Overall, full color stickers can last anywhere from a few months to several years depending on the materials and conditions in which they are used, and proper care and maintenance can help extend their lifespan.

Conclusion

Full color sticker printing is a versatile and customizable option for a wide range of applications. With a variety of materials, finishes, shapes, and sizes available, full color stickers can be designed to suit any purpose, from branding and marketing to personal expression and decoration. Overall, full color sticker printing offers a creative and effective way to communicate messages, express individuality, and enhance the appearance of any surface.

Popular Posts: