Polyurethane domed decals are a popular type of labeling and branding solution that features a three-dimensional, bubble-like appearance.

They are commonly used on a wide range of products, including electronics, automobiles, promotional items, and more. They are an effective way to add a professional, high-quality look to any product or project.

What are Polyurethane Domed Decals?

Polyurethane domed decals that feature a unique three-dimensional appearance. These decals are made from a flexible, durable material known as polyurethane, which is poured over a printed graphic or design. The polyurethane material creates a raised, bubble-like effect that gives the decal a unique look and feel. The domed finish is glossy and smooth, providing a high-quality appearance that enhances the visual appeal of the decal.

Polyurethane domed decals that feature a unique three-dimensional appearance. These decals are made from a flexible, durable material known as polyurethane, which is poured over a printed graphic or design. The polyurethane material creates a raised, bubble-like effect that gives the decal a unique look and feel. The domed finish is glossy and smooth, providing a high-quality appearance that enhances the visual appeal of the decal.

Polyurethane domed decals are also resistant to scratches, fading, and other types of wear and tear, making them ideal for use on a wide range of products and surfaces. They can be customized with a variety of colors, shapes, and sizes, and are commonly used for branding, promotional items, and product identification.

What is Domed Finish in Decals?

A domed finish in decals is a unique three-dimensional, bubble-like effect that gives the decal a raised, glossy appearance. This finish is achieved by pouring a liquid polyurethane material over a printed graphic or design, which is then allowed to cure and harden. The result is a smooth, rounded surface that enhances the visual appeal of the decal and provides added protection against scratches and other types of wear and tear. The domed finish can be customized with a variety of colors, shapes, and sizes, making it a popular choice for branding, product identification, and promotional items.

What is the Best Resin for Doming Decals?

When it comes to selecting the best resin for doming decals, polyurethane is the most commonly used material. Polyurethane resin is a versatile and durable material that can be poured over a printed graphic or design to create a raised, glossy finish. It is resistant to scratches, fading, and other types of wear and tear, making it ideal for use on a wide range of products and surfaces.

When it comes to selecting the best resin for doming decals, polyurethane is the most commonly used material. Polyurethane resin is a versatile and durable material that can be poured over a printed graphic or design to create a raised, glossy finish. It is resistant to scratches, fading, and other types of wear and tear, making it ideal for use on a wide range of products and surfaces.

In addition, polyurethane resin is flexible and can conform to curved or irregular surfaces, allowing for greater design flexibility. Other types of resins, such as epoxy or acrylic, can also be used for doming decals, but they may not provide the same level of durability and flexibility as polyurethane.

How Thick is the Polyurethane Resin in Domed Decals?

The thickness of the polyurethane resin in domed decals can vary depending on the specific application and desired outcome. Typically, the resin layer is between 1-3 millimeters thick, but it can be thicker or thinner depending on the design and intended use of the decal. The thickness of the resin layer can affect the durability and flexibility of the decal, as well as its overall appearance.

A thicker resin layer may provide greater protection against scratches and other types of wear and tear, but it may also make the decal less flexible and more difficult to apply. Conversely, a thinner resin layer may be more flexible and easier to apply, but it may not provide the same level of protection against damage. Ultimately, the thickness of the polyurethane resin in domed decals will depend on the specific needs and requirements of the project.

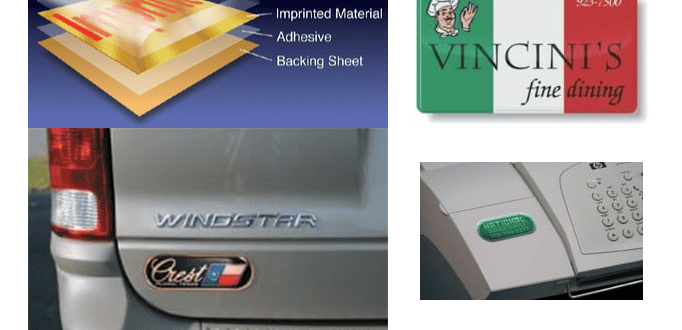

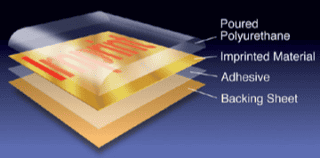

How Polyurethane Domed Decals are Made?

Polyurethane domed decals are made through a multi-step process that involves several levels. The process begins with a liner backing, which is a protective layer that is removed before the decal is applied. Next, an adhesive layer is applied to the substrate. The printed artwork is then printed to the adhesive vinyl, either by screen or digital printing, ensuring high-quality, vibrant colors.

Polyurethane domed decals are made through a multi-step process that involves several levels. The process begins with a liner backing, which is a protective layer that is removed before the decal is applied. Next, an adhesive layer is applied to the substrate. The printed artwork is then printed to the adhesive vinyl, either by screen or digital printing, ensuring high-quality, vibrant colors.

After the graphics are printed, a liquid polyurethane material is poured over the printed graphic or design. This material is allowed to cure and harden, creating a raised, glossy finish that gives the decal its unique three-dimensional appearance.

Polyurethane Domed Decals Product Features

- Three-dimensional, bubble-like appearance

- Made from flexible, durable polyurethane material

- Raised, glossy finish enhances visual appeal

- Resistant to scratches, fading, and wear and tear

- Customizable with a variety of colors, shapes, and sizes

- Ideal for branding, product identification, and promotional items

- Can conform to curved or irregular surfaces

- Thickness of resin layer can vary for specific applications

- Multi-step process involves liner backing, adhesive, substrate, printed artwork, and top clear polyurethane dome

- Adds professional, high-quality look to any product or project

How Flexible or Rigid are Domed Decals? Can They Be Adjusted?

Polyurethane domed decals are flexible and can conform to curved or irregular surfaces, making them highly versatile and adaptable. The flexibility of the decals is due to the properties of the polyurethane material, which is both durable and flexible. The level of flexibility can be adjusted based on the specific needs and requirements of the project.

Polyurethane domed decals are flexible and can conform to curved or irregular surfaces, making them highly versatile and adaptable. The flexibility of the decals is due to the properties of the polyurethane material, which is both durable and flexible. The level of flexibility can be adjusted based on the specific needs and requirements of the project.

For example, if a decal needs to be applied to a highly curved surface, a thinner layer of polyurethane resin may be used to ensure greater flexibility. Conversely, if the decal needs to be more rigid, a thicker layer of resin can be used. The level of flexibility can also be adjusted by changing the type of adhesive used or by altering the curing process.

Why Do Some Domed Decals Turn Yellow?

One of the main reasons why some domed decals turn yellow over time is due to exposure to UV light. The polyurethane material used to create the domed decal is not immune to the effects of UV light. Over time, exposure to UV light can cause the polyurethane material to break down, which can lead to yellowing or discoloration of the decal. Also, exposure to heat or other environmental factors can also contribute to yellowing.

To prevent yellowing, it is important to use high-quality polyurethane material that is specifically designed for outdoor use and to limit the decal’s exposure to UV light. Applying a UV-resistant coating or placing the decal in a location that is not exposed to direct sunlight can also help to prevent yellowing over time.

Are Polyurethane Domed Decals Scratch Proof?

While polyurethane domed decals are resistant to scratches, they are not completely scratch-proof. The thick layer of polyurethane resin that covers the printed artwork provides a durable, protective layer that can withstand a lot of wear and tear. However, certain types of abrasives or sharp objects can still scratch or damage the surface of the decal.

The level of scratch resistance can also depend on the thickness of the resin layer and the specific properties of the polyurethane material used. To maintain the appearance and longevity of the decal, it is important to avoid using abrasive cleaners or tools that can scratch the surface.

Conclusion

Polyurethane domed decals are a highly versatile and durable solution for branding, product identification, and promotional items. The multi-step process used to create these decals results in a unique, three-dimensional appearance that adds a professional, high-quality look to any product or project. Overall, they are a versatile, durable, and visually appealing solution for a wide range of products and surfaces.

Popular Posts: