Stretchable Fabric Material Dye Sublimation Printed for Trade Show Banners Wholesale For Brokers & Resellers

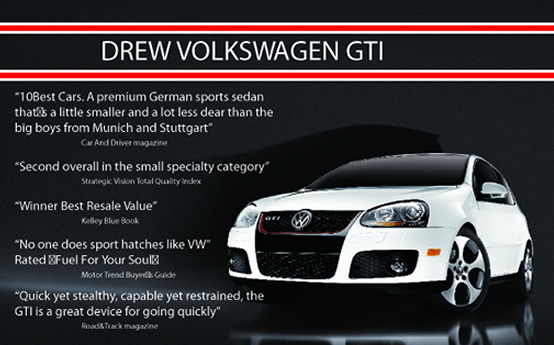

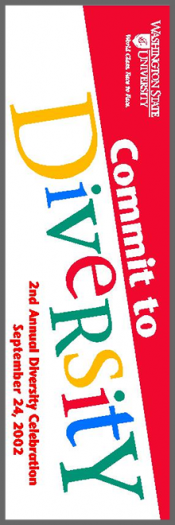

Dye sublimation printing on Fabric Banners on Power Stretch Warp Knit Polyester, an 8.8 oz. heavy-weight stretchable fabric material that gives opacity and great definition on all colors. This fabric gives equal stretch in both directions and offers excellent wrinkle resistant characteristics producing wrinkle free fabric banner and is highly recommended for trade show booths and displays.

What is Dye Sublimation Printing

Dye sublimation printing is a heat-transfer process, whereby a graphic is printed in reverse on a special transfer paper and heat-transferred while applying high pressure to polyester fabric banner material. After the paper is printed, the ink/paper is heated to 400+ degrees and using pressure on the paper/ink/fabric, the ink turns into a gas and “sublimates” itself into the fabric – hence the term dye sublimation.

Compared to direct solvent print to fabric, this process provides more vibrant colors and a photo-clear definition. Another advantage of dye sub fabric banner printing process is that these fabric banners are machine washable on a gentle cycle with mild detergent. You can’t do this with solvent-printed fabrics.

Product Features and Options

We provide wholesale dye sublimation printing services on Power Stretch Cloth Banners with the following options and/or features:

- FREE set-up on most banner printing

- Hot knife edge-finishing

- Hems and/or Grommets

- Pole Pockets

- Hem Reinforcing

- Design Services

- Ship in approx. 3 to 5 working days

- Rush Orders & Expedited Shipping

- Note: We cannot guarantee exact color matching for all Pantone™ colors

Where to Use Stretchable Fabric Banners

Dye sub Power Stretch Fabric Banners are mainly used for:

- Trade Show Displays

- Interior P.O.P. Displays

- Complex Displays

- Compound Curve Displays

- Frame Displays, Etc.

Testimonial

OMG The banners came out FANTASTIC!!! I just can’t get over the color on them and how nice they look… Big kudos to you and your team! Please pass along how happy I am! :) Thank you again SO much…I’m already happily planning next year’s order ( but hopefully we won’t have to rush you next time lol).

– Kellee at KelleeArt Design, FL

Get a Quote Now!

Visigraph is a wholesale domestic and import broker, and therefore, we require a minimum order of $500USD for ALL wholesale orders.

All fields marked with star (*) are required.

Large Quantity Quotations

If you need large quantities of power stretch dye sub fabric banners for trade show, call us at 509-483-8000, email our sales department directly at sales@visigraph.com, or fill out our Get A Quote form to know how much a custom fabric cost.

If you need large quantities of power stretch dye sub fabric banners for trade show, call us at 509-483-8000, email our sales department directly at sales@visigraph.com, or fill out our Get A Quote form to know how much a custom fabric cost.

The Visigraph 100% Satisfaction Guarantee

We pay careful attention to every detail on every order we receive, and our 100% Satisfaction Guarantee is just what it says…you’ll love our fabric banner printing or we’ll re-do them. It doesn’t happen often, but hey, we’re human too! Rest assured, though, that if it does, we’ll fix’em free of charge and with no hassle.

Calculating the Size of your Power Stretch Dye Sub Fabric Banner

Height x Width = Number of Square Feet. For example, if you have a banner that is 5ft. x 5ft.- 5 x 5 = 25 square feet

What is Polyester Fabric

Polyester is a polymer-based material which is a woven fabric. Improvements have been made to the materials so that now you can get anything from smooth poly knits to poly silks, poly flags, and sheer fabrics for almost any event, indoor or out.

Its is very stain resistant, and only certain specialty dyes are able to permanently color the fabric.

Polyesters have also been made to mirror natural fibers. An example is “polysilk” fiber, obviously mimicking silk. Polyknits have been used for 50+ years, but now can emulate cotton or wool or taffeta or other natural or synthetic fibers, often with superior durability.Some polyesters are “thermoplastics,” and these are the type used in polyester fabric.

Natural fibers cannot be used in the print process due to their cellular structure and the chemistry of dye sublimation.

The Process of Dye Sublimation Printing

Traditional dye sub printing utilizes a transfer paper which is printed with the CMYO inks in reverse. CMYO colors (Cyan-Magenta-Yellow-Overcoating) is different from inkjet banner printing (on vinyl or fabric) which uses CMYK (cyan-magenta-yellow-black) because the black is eliminated and the clear overcoat is used instead.

This overprint is both a UV protectant and helps to create a water-resistant coating for polyester banners and displays, t-shirts, table covers, sportswear, flags, and other items that require high definition printing.

An image or photograph is sent to the printer, and it prints the image, in reverse, onto a sheet of transfer media, a treated paper. It is then “married” to the chosen fabric, and sent through another unit with heated pressure rollers.

Once the paper is matched to the fabric, it is run through heated rollers at high pressure. The rollers are heated to just under 400 degrees Fahrenheit or 210 degrees Celsius.

With the heat and the pressure, the pores of the polyolefin fabric expand and open, and the dye from the transfer paper is converted to a gaseous state and the pressure from the rollers forces it into the open cells of the poly fabric, thus infusing the color to become part of the fabric itself. This creates a continuous tone print which cannot be achieved using an inkjet printer because of the dot pattern laid down by the inkjets.

As the fabric cools, the pores close back up around the dye, but are now whatever color the dye was that infused them. This process is somewhat like photo printing in that the tones are continuous, unlike the dot pattern of an inkjet printer. This also is what creates the richness of color, tone, and continuity in dye sublimation printed fabric graphics that catch everyone’s eyes.

Advantages of Using Dye Sublimation Fabric Banners

The sublimation printing permanently infuses the poly fabric with color during the printing process so that you can send these banners through the washer without color loss, and a rain storm would be more gentle than your average washing machine, we’d think.

The image is a part of the fabric, so it doesn’t peel off like ink on the surface of fabric or other materials and will not fade for many years.

The colors can be more brilliant than other types of printing because of the process of dye sublimation and the continuous tones that are achieved when the dye converts to a gaseous state.

Continuous tone printing is accomplished reproducing prints muck like a photograph. It creates brighter and smoother color variations and transitions than you’ll find with inkjet printing, and a superior overall look, in our opinion.

Banner Care

If you can’t fit the banner or banners in your washer, then you’ll need to manually wash them, whether when you’re hanging them or washing them in a large tub or barrel. No matter which route you take, make sure your detergent is tough against grease.

Once you’ve washed your dye sub cloth banners, the best practice is to hang them up to dry. If you don’t have this option, and they’ll fit in a dryer, go ahead and dry them that way. Make sure you don’t leave them in the dryer once it stops, as it’ll create wrinkly banners.

Once the fabric banner has dried, you can also use an iron on low heat to iron out any wrinkles that may have occurred in the drying process. Now you have a bright and clean banner to hang up!

Sun and wind are the enemies of all banners and their installations, but on flags, if secured over a pole, wind is less a factor than the sun will be.

Most digitally printed banners, though, should, if properly installed, last at least 3 years outdoors, though I’ve seen them last 10 years in the case of one very cheap client. There is not much you can do to protect a banner from the sun, but a good quality ink should keep them lasting as long as you’ll need them to advertise your company or event.

Popular Posts Related to the Products: