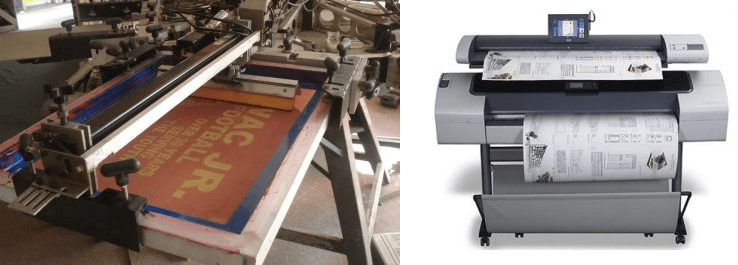

Several hundred years ago when I made the fateful decision to get into the signage business, my first position was screen printing signs. Back when I started, you could be make graphic displays with lacquer inks and get high at the same time…those were the days!

Many companies who used to be screen pressing have switched over to digital printing, but there are still numerous companies who do screen-print press, and as far as I can tell, it isn’t going away anytime soon, as was prognosticated by myself and other sign experts 5 years ago.

Digital and Screen Printing: Speed vs. Run Size

While digital sign printing has increased in popularity, it still cannot match the speed of screen printing, especially as the quantities increase. Digital processing, though, has rocked the signage world over the past decade with it’s cost-effective, full color press of short runs of banners, posters, display graphics, decals, and other great products that many companies may only need a few to a few hundred of.

Especially on lower quantities of colors and higher quantities, it takes around an hour per color to set up to run each color for screen pressing on average. The variety of materials that can be screen-printed is wider than most digital press companies are able to do unless they have a more recently developed digital UV flatbed printer, in which case they may be close to even.

The Basics of Screen Printing

There are many types of ink used in screen printing signs, but the most common ink bases are lacquer-based and UV inks. Within those categories there are inks for vinyl, various plastics, wood, and more. It may be good to note here that you can also print cloth or fabric banners with digital UV printers now as well, but we’ll cover that exhaustively in another article later.

The basic process involved in screen printing contains several steps:

Screens

1) You need to start with a good frame with the right mesh fabric for the ink you’re printing with. If you are using UV inks, the mesh will be finer than with lacquer-based inks, as the color particles are ground more finely. Using a “Newton Meter”, you check to make sure the screen has proper tension, usually around 18 to 22 N/cm, but sometimes higher.

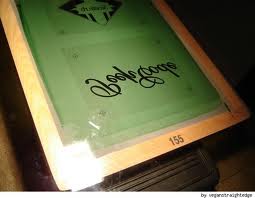

Newton Meter

2) You’d coat your screen with a photo-reactive solution (usually) and allow it to dry in a darkroom – this can take 15 minutes to a couple hours, depending on the humidity of the room. After it has dried, it’s time to affix the film positive image on it’s printing side (bottom). Film positives can be printed on an image setter or cut from pressure-sensitive vinyl and applied to a clear acetate, depending on how high tech your shop is.

When I started doing this process, we literally used a light bulb and a sheet of glass (or the sun if it was shining) to expose our screens…over time, we made enough money to purchase a “proper” vacuum frame and exposure unit, and exposing our films with the proper equipment became much easier.

3) After the film has been exposed, you remove the screen to a washout tank. We use a 1500PSI pressure washer to develop the film (not too close or we’d blow the emulsion out of the screen). When the emulsion that had been covered by the film positive has been washed out, we have a screen printable image on the screen, or whatever we are pressing.

4) After the screen is dried, it’s moved to the press and set-up with the substrate, micro-adjusted, taped off (so the ink stays on the screen), and we’re ready to start screen pressing. With UV screen print method, the sign is printed on the press and dropped onto a belt that carries it through a UV dryer. It is manually stacked and then are delivered to the client.

Find out more on screen printing signs and see what other classes can be crafted with other print options.

Popular Posts: