In this installment of the history of signs and graphics printing, I’ll talk about the vast improvements in from the mid-1800’s until late in the 20th century. And where the two trades intersected to create a significant change for many sign makers.

To recap the previous three articles on this history series, we’ve talked about how signage came to be used in the West and the wood type gave way (mostly) to electrical and neon in the past 100 years or so. The end products have never been so fascinating – much of this information is new to me, so I hope it is for you as well!

Sign Graphics and Printing Since the 1860’s

While this is part 4 of this series, it is really the second part of the history and how eventually manufacturers came to integrate printing into signs.

The last major improvement we talked about in the last article was roll printing, in which large rolls of media could be printed at high speeds. This improvement took place about 1863.

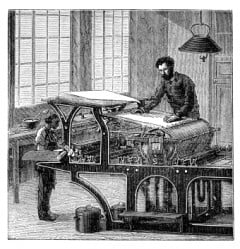

Lithography Press

I’m going to backtrack slightly to 1796. A printing process called Lithography was developed by an innovative Bavarian author by the name of Aloys Senefelder. The reason I am backtracking to this method is because it became one of the methods used in by makers later, or at least in part.

I’m going to backtrack slightly to 1796. A printing process called Lithography was developed by an innovative Bavarian author by the name of Aloys Senefelder. The reason I am backtracking to this method is because it became one of the methods used in by makers later, or at least in part.

In Lithography, chemicals are used to create an image. Without going into the gory details (which are really above my head and I’m just not into chemistry – I just like what it can do!), we’ll just say there’s some positive and negative images, that combined, produces very nice signs and graphics. Today, most books are pressed using offset lithography, or offset printing for short. Posters (large runs), maps, packaging, and newspapers are also produced with this method, as well as some other types.

Major improvements in Lithography came later into the 19th century with the addition of color (chromolithography). This process is reputed to be the antecedent to 4-color process printing which is the basis for most color print processing today.

Another improvement to lithography was the addition of offset press, in which the inked plate was transferred to a rubber blanket, and then to the printing substrate such as metal or paper or plastic. Again, there’s some chemicals and water used in this process that I won’t go into, but this improvement is still used to this day in books, packaging, and many other high speed print items.

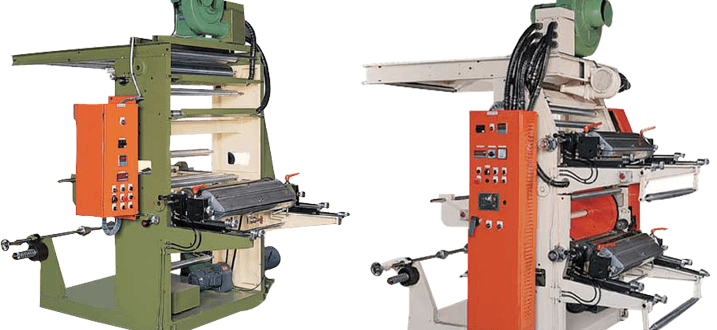

Flexographic Press

Another innovation known today as Flexographic pressing. Initially, in 1890, when the first rubber printing plates were used with water-based inks, the results were fast but smeared too easily. New aniline inks were developed within 15 to 20 years that worked great, particularly with food packaging. The process was called “aniline printing” at that time, but the inks were classified in the 1940’s by the FDA as unsafe for food packaging, and although new, safer inks were developed in 1949, the food industry shied away from aniline method, so in 1951, Frank Moss renamed aniline to flexographic imprinting, and this category was reborn.

Another innovation known today as Flexographic pressing. Initially, in 1890, when the first rubber printing plates were used with water-based inks, the results were fast but smeared too easily. New aniline inks were developed within 15 to 20 years that worked great, particularly with food packaging. The process was called “aniline printing” at that time, but the inks were classified in the 1940’s by the FDA as unsafe for food packaging, and although new, safer inks were developed in 1949, the food industry shied away from aniline method, so in 1951, Frank Moss renamed aniline to flexographic imprinting, and this category was reborn.

In the 1990’s, rubber plates were replaced with photopolymer plates, and the quality improved dramatically with this innovation. The photopolymer plates are also easier to create now, and digital “direct-to-plate” technology has been developed which has also made the process much faster as well. Finally, with these improvements, lithography now rivals offset press quality.

There’s more knowledge to grasp when it comes to printing methodology. Click here to read the final part of this history of signs and graphics series.

Popular Posts: